The NACA inlet is progressing well.

That technique of micro and neat resin didn't really work out for me.

Maybe I rushed it with laying up before the black paint was properly hard but it didn't release at all.

I ended up having to dig it out with a screwdriver then Dremel away the remaining thin layer of foam and paint.

So for the next part (the cockpit vent cavity) I didn't bother with the resin or paint. I just put a thin layer of micro on the foam to fill in the little pinholes and then gave that a light sand and layed up straight over that.

Same method and time to get the foam out and less work than the painting and waxing so until I find out why it didn't work I won't bother with it again.

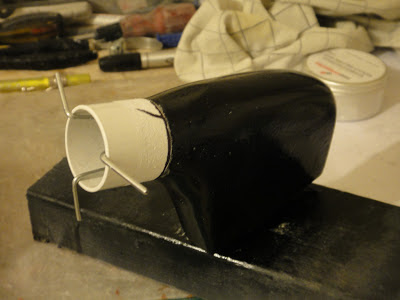

You'll notice that I bonded in a piece of PVC pipe to make a strong connection for the scat hose.

I need not have bothered with this as 3 or 4 layers of fiberglass is strong enough - besides after talking to Pete I found out he doesn't use a hose clamp but just some silicone sealant and tape to hold it on.

As it turns out the vent cavity did not fit in the space between the cell and fuse anyway so I had to cut that PVC section off and oval the fiberglass.

Luckily that piece was not fully set when I did that and I was able to put it in the vice overnight and this set it in an oval.

I should point out why I am going with this sealed hose method rather than the factory set up.

Their set up involves sealing the cell to the fuse over a large area with expanding foam to create an air tight cavity.

I'm not sure that is any easier to do and would leave no where for rain water or any other object that gets in to find it's way out.

I've built a water drain into the bottom of the vent cavity and will run a small tube from the base of that to the bottom of the fuse as a drain.

Other than this work I've just been doing more filling and sanding in the cockpit interior - getting there...

On the rudder pedals the manual calls for inserting 220mm of the Polyamid tube into the S shaped pieces of metal on the sides of the pedals.

These are so the rudder cables don't wear or catch on these tubes.

Well guess what? The tube doesn't fit!

I tried and the outside diameter is much too big to fit into these tubes...

I got some other tube from another supplier and that only just fitted - using WD40 and a bit of patience - and it was 1mm less diameter than the factory supplied tube so there was no way that was ever going to fit.

FYI - 6mm outside diameter and at least 4mm inside diameter will do the job.

This weekend I am away on the LAA Electrics and Avionics course so probably won't update the blog for another 2 weeks.

|

| Tube in rudder pedals |

|

| Mold for NACA connector with PVC pipe on end |

|

| Seat holding blocks |

|

| NACA duct and connecter bonded together |

|

| Cabin vent assembly before bonding in. |

|

| Test fit of Vent cavity |

|

| NACA duct test fit |

|

| Moment of truth - Bonding it in |

|

| Inside view before bonding in |

No comments:

Post a Comment