From Italy comes the ICP M09.

80hp

Based on a motorcycle V-twin of 1225cc.

It's a bolt on package with everything included - just bolt onto your engine mount and connect up the electric and fuel lines.

Priced between 12 and 13 K euros.

It will be formally released at Aero Friedrichshafen in April.

I note that it's installed weight is 5 kg heavier than the UL260iSA and it produces 27 less hp.

It's not for me but it may work well in a Twister for someone on a budget.

More detail and pics on this link.

http://www.eaa.org/news/2012/2012-11-21_ICP-announces-new-LSA-engine.asp

Tuesday 29 January 2013

Monday 28 January 2013

Week 76 - Air vent, static ports, rudder cable tubes

Hours to date: 782.0

I've had a quiet couple of weeks on the kit due to the extremely cold weather we've had - minus 4 at night and not much warmer during the day - which kept me out of the garage. Plus I spent 3 days at the LAA Electrics and Avionics courses.

The Electrics day was pretty intense and my brain turned to mush by mid afternoon.

The Avionics day was much more relaxed - discussing all the nice toys you can put in light aircraft these days.

I came away feeling much more confident about installing the electrics and I haven't changed my panel layout much at all - just moved the fuses away from the panel face. I will install a small fuse box behind the panel.

The NACA inlet is coming along well - still got some finishing to do to the inlet and I finally got around to bonding in the outlet cavity.

First off I put a water drain tube on the bottom of the cavity though.

As you can see it was 'clamps for Africa' on the bonding of the outlet cavity.

After that I installed the tubes that the rudder cables run in.

It was like trying to wrestle a snake working with these tubes. They've been coiled up for so many years that they do not want to lay flat. You've got to thread them in a small space in between the safety cell and fuselage. The starboard side was easier as I could help to feed it through with my hand inside the air vent hole.

I've just taped them in place for the moment. I'll install them properly when I bond on those fiberglass straps I made up recently.

Next up was installing the static ports. I got these from Aircraft Spruce and they are specifically designed for composite aircraft. (Pete uses gliding ones which I found too hard to get hold of). Pretty straight forward - just cut a hole and bond in with flock. The location of the ports I got from Pete and for your information is 1000mm forward of the leading edge of the tailplane and then 435mm down from the centreline of the fuselage (use a flexible ruler for that).

I've also got the transponder and radio antennas (aerials) to install - more about those in the next post.

Final pic is of my shiny new military style stick grip from Infinity. A nice bit of kit - I won't be using many of the buttons - most likely just the push to talk. I may put the radio frequency flip function on it if my radio supports it.

Also the observant amongst you will see that the control column is not the factory supplied one. Pete has had these made up (at great expense - don't ask!) and approved by the LAA as a mod. The two things that are different are the bearings at the bottom and the bracket for mounting the trim at the top. It does feel like a quality piece of kit now - I think it's important to have primary controls that feel just right and will stay that way without wearing out.

Once I've finished the NACA duct I'll start on installing the instrument panel.

I've had a quiet couple of weeks on the kit due to the extremely cold weather we've had - minus 4 at night and not much warmer during the day - which kept me out of the garage. Plus I spent 3 days at the LAA Electrics and Avionics courses.

The Electrics day was pretty intense and my brain turned to mush by mid afternoon.

The Avionics day was much more relaxed - discussing all the nice toys you can put in light aircraft these days.

I came away feeling much more confident about installing the electrics and I haven't changed my panel layout much at all - just moved the fuses away from the panel face. I will install a small fuse box behind the panel.

The NACA inlet is coming along well - still got some finishing to do to the inlet and I finally got around to bonding in the outlet cavity.

First off I put a water drain tube on the bottom of the cavity though.

As you can see it was 'clamps for Africa' on the bonding of the outlet cavity.

After that I installed the tubes that the rudder cables run in.

It was like trying to wrestle a snake working with these tubes. They've been coiled up for so many years that they do not want to lay flat. You've got to thread them in a small space in between the safety cell and fuselage. The starboard side was easier as I could help to feed it through with my hand inside the air vent hole.

I've just taped them in place for the moment. I'll install them properly when I bond on those fiberglass straps I made up recently.

Next up was installing the static ports. I got these from Aircraft Spruce and they are specifically designed for composite aircraft. (Pete uses gliding ones which I found too hard to get hold of). Pretty straight forward - just cut a hole and bond in with flock. The location of the ports I got from Pete and for your information is 1000mm forward of the leading edge of the tailplane and then 435mm down from the centreline of the fuselage (use a flexible ruler for that).

I've also got the transponder and radio antennas (aerials) to install - more about those in the next post.

Final pic is of my shiny new military style stick grip from Infinity. A nice bit of kit - I won't be using many of the buttons - most likely just the push to talk. I may put the radio frequency flip function on it if my radio supports it.

Also the observant amongst you will see that the control column is not the factory supplied one. Pete has had these made up (at great expense - don't ask!) and approved by the LAA as a mod. The two things that are different are the bearings at the bottom and the bracket for mounting the trim at the top. It does feel like a quality piece of kit now - I think it's important to have primary controls that feel just right and will stay that way without wearing out.

Once I've finished the NACA duct I'll start on installing the instrument panel.

|

| Bonding in vent cavity |

|

| Rudder cable tubes - rough fit before installing. |

|

| NACA duct - still some finishing to do here. |

|

| Static port |

|

| Infinity Stick grip on mod control column |

Thursday 24 January 2013

Great Aircraft Electrics resource

And it's free.

Download the whole 307 pages from here:

http://www.aeroelectric.com/Catalog/pub/pub.html

Actual link to file is here: http://www.aeroelectric.com/Book/AEC12A_PDF.zip

The author is the guru of aircraft electrics, Bob Nuckolls.

Unfortunately the download is separate PDFs for each chapter - I have combined them all into one PDF and can send the link to that if anyone is interested.

Download the whole 307 pages from here:

http://www.aeroelectric.com/Catalog/pub/pub.html

Actual link to file is here: http://www.aeroelectric.com/Book/AEC12A_PDF.zip

The author is the guru of aircraft electrics, Bob Nuckolls.

Unfortunately the download is separate PDFs for each chapter - I have combined them all into one PDF and can send the link to that if anyone is interested.

Thursday 17 January 2013

First Italian Twister flies

Actually it was built in Lithuania but this is the first Twister registered in Italy.

Looks good in Silver.

Powered by a standard 97hp UL Power engine.

Looks good in Silver.

Powered by a standard 97hp UL Power engine.

Tuesday 15 January 2013

Monday 14 January 2013

Week 74 - NACA inlet

Hours to date: 771.25

The NACA inlet is progressing well.

That technique of micro and neat resin didn't really work out for me.

Maybe I rushed it with laying up before the black paint was properly hard but it didn't release at all.

I ended up having to dig it out with a screwdriver then Dremel away the remaining thin layer of foam and paint.

So for the next part (the cockpit vent cavity) I didn't bother with the resin or paint. I just put a thin layer of micro on the foam to fill in the little pinholes and then gave that a light sand and layed up straight over that.

Same method and time to get the foam out and less work than the painting and waxing so until I find out why it didn't work I won't bother with it again.

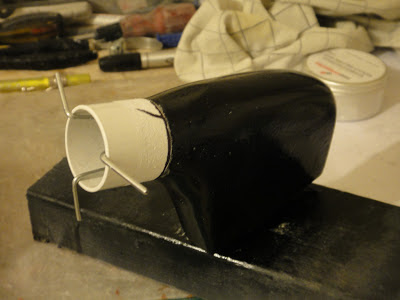

You'll notice that I bonded in a piece of PVC pipe to make a strong connection for the scat hose.

I need not have bothered with this as 3 or 4 layers of fiberglass is strong enough - besides after talking to Pete I found out he doesn't use a hose clamp but just some silicone sealant and tape to hold it on.

As it turns out the vent cavity did not fit in the space between the cell and fuse anyway so I had to cut that PVC section off and oval the fiberglass.

Luckily that piece was not fully set when I did that and I was able to put it in the vice overnight and this set it in an oval.

I should point out why I am going with this sealed hose method rather than the factory set up.

Their set up involves sealing the cell to the fuse over a large area with expanding foam to create an air tight cavity.

I'm not sure that is any easier to do and would leave no where for rain water or any other object that gets in to find it's way out.

I've built a water drain into the bottom of the vent cavity and will run a small tube from the base of that to the bottom of the fuse as a drain.

Other than this work I've just been doing more filling and sanding in the cockpit interior - getting there...

On the rudder pedals the manual calls for inserting 220mm of the Polyamid tube into the S shaped pieces of metal on the sides of the pedals.

These are so the rudder cables don't wear or catch on these tubes.

Well guess what? The tube doesn't fit!

I tried and the outside diameter is much too big to fit into these tubes...

I got some other tube from another supplier and that only just fitted - using WD40 and a bit of patience - and it was 1mm less diameter than the factory supplied tube so there was no way that was ever going to fit.

FYI - 6mm outside diameter and at least 4mm inside diameter will do the job.

This weekend I am away on the LAA Electrics and Avionics course so probably won't update the blog for another 2 weeks.

The NACA inlet is progressing well.

That technique of micro and neat resin didn't really work out for me.

Maybe I rushed it with laying up before the black paint was properly hard but it didn't release at all.

I ended up having to dig it out with a screwdriver then Dremel away the remaining thin layer of foam and paint.

So for the next part (the cockpit vent cavity) I didn't bother with the resin or paint. I just put a thin layer of micro on the foam to fill in the little pinholes and then gave that a light sand and layed up straight over that.

Same method and time to get the foam out and less work than the painting and waxing so until I find out why it didn't work I won't bother with it again.

You'll notice that I bonded in a piece of PVC pipe to make a strong connection for the scat hose.

I need not have bothered with this as 3 or 4 layers of fiberglass is strong enough - besides after talking to Pete I found out he doesn't use a hose clamp but just some silicone sealant and tape to hold it on.

As it turns out the vent cavity did not fit in the space between the cell and fuse anyway so I had to cut that PVC section off and oval the fiberglass.

Luckily that piece was not fully set when I did that and I was able to put it in the vice overnight and this set it in an oval.

I should point out why I am going with this sealed hose method rather than the factory set up.

Their set up involves sealing the cell to the fuse over a large area with expanding foam to create an air tight cavity.

I'm not sure that is any easier to do and would leave no where for rain water or any other object that gets in to find it's way out.

I've built a water drain into the bottom of the vent cavity and will run a small tube from the base of that to the bottom of the fuse as a drain.

Other than this work I've just been doing more filling and sanding in the cockpit interior - getting there...

On the rudder pedals the manual calls for inserting 220mm of the Polyamid tube into the S shaped pieces of metal on the sides of the pedals.

These are so the rudder cables don't wear or catch on these tubes.

Well guess what? The tube doesn't fit!

I tried and the outside diameter is much too big to fit into these tubes...

I got some other tube from another supplier and that only just fitted - using WD40 and a bit of patience - and it was 1mm less diameter than the factory supplied tube so there was no way that was ever going to fit.

FYI - 6mm outside diameter and at least 4mm inside diameter will do the job.

This weekend I am away on the LAA Electrics and Avionics course so probably won't update the blog for another 2 weeks.

|

| Tube in rudder pedals |

|

| Mold for NACA connector with PVC pipe on end |

|

| Seat holding blocks |

|

| NACA duct and connecter bonded together |

|

| Cabin vent assembly before bonding in. |

|

| Test fit of Vent cavity |

|

| NACA duct test fit |

|

| Moment of truth - Bonding it in |

|

| Inside view before bonding in |

Wednesday 2 January 2013

Week 72 - Seat, panel, NACA inlet

Hours to date: 747.25

As you can see I've nearly reached 750 hours - but does this mean I'm halfway?

I don't think so, as the oil cooler mod has showed me how much more time is taken when you go 'freestyle'.

I've still got the cowling to do and that will be at least another 200 hours. So I may be looking at more like 1750 to 2000 hours rather than my initial estimate of 1500 hours.

If it does turn out to be 1500 hours then I'll be looking at a first flight in about May of 2014 (if I keep up my current average of work hours).

In the last few days I've been working on cockpit related stuff.

The panel is coming along nicely - first coat of primer is on and there is a little more filling to do but it is close to receiving it's final prime and paint.

I'm going to go for a matt grey charcoal on the panel. I'll most likely go for a charcoal grey on the interior of the cockpit too.

I've also bought a Winter Altimeter to go with the ASI - so that's all my 'steam' gauges bought.

I'm going to hold off on buying the EFIS, Radio and Transponder until after my Avionics course as I want to see what they say about my proposed layout.

The panel is mounted with 3 right angle pieces of fiberglass - which were not part of the kit - so I have made up my own.

I just used a block of wood with duct tape on it then laid up 8 layers of fabric on it and finished off with a layer of peel ply. Then I wrapped the whole thing in plastic, stretched that tight and taped it down so the fabric would keep to the edge of the block of wood and not get any air bubbles in it.

Worked out pretty good.

I used the same method to make up some 'straps' for holding the rudder pedal tubes (and other static tubes) in place.

I used a piece of the tube taped onto a block of wood with duct tape.

This time I put the peel ply down first so that the bonding surface when done will be ready to use with no further work.

These are just stuck on with flock (with the tube taped in place till the flock hardens).

I made up all the blocks of plywood that hold the seat in position (I didn't take a photo for some reason). But then found that the seat itself doesn't fit very well at the front so it needed extending on the lower sides.

Pete says that final fitting is done with a load of micro on the floor of the cockpit (already covered with duct tape) and then the seat is just pushed into the micro and left to set. This should give a perfect fit when done.

Next up is the NACA inlet for the cockpit ventilation.

The duct supplied is for the old system of close-able vent. The manual calls for a air tight cavity to be made between the cell and the fuselage - made with expanding foam. Pete does not use this method and instead just has a scat hose connected to the NACA duct (of his own making) and then that connects to a cavity behind the vent control in the cockpit itself. Again this cavity is made by Pete.

I've decided to go the same route and modify the supplied NACA inlet by building a section behind it that transfers the air from the inlet to a hose.

I've sculpted this out of foam and it will be bonded onto the duct as a one piece unit when it is done.

I'm also trying a new method of making a mold plug out of foam. Rather than the sealing with micro and then sanding method. I read about it online and Pete says he uses it too so I thought I'd give it a shot.

Basically you just apply a thin layer of Micro slurry to the foam to fill any pin holes then straight away apply a thick coat of neat resin.

Allow that to set then just give the resin a light sand before painting and polishing and finally waxing.

Time will tell if this is the right way to go - it would certainly save a lot of time if it works.

As you can see I've nearly reached 750 hours - but does this mean I'm halfway?

I don't think so, as the oil cooler mod has showed me how much more time is taken when you go 'freestyle'.

I've still got the cowling to do and that will be at least another 200 hours. So I may be looking at more like 1750 to 2000 hours rather than my initial estimate of 1500 hours.

If it does turn out to be 1500 hours then I'll be looking at a first flight in about May of 2014 (if I keep up my current average of work hours).

In the last few days I've been working on cockpit related stuff.

The panel is coming along nicely - first coat of primer is on and there is a little more filling to do but it is close to receiving it's final prime and paint.

I'm going to go for a matt grey charcoal on the panel. I'll most likely go for a charcoal grey on the interior of the cockpit too.

I've also bought a Winter Altimeter to go with the ASI - so that's all my 'steam' gauges bought.

I'm going to hold off on buying the EFIS, Radio and Transponder until after my Avionics course as I want to see what they say about my proposed layout.

The panel is mounted with 3 right angle pieces of fiberglass - which were not part of the kit - so I have made up my own.

I just used a block of wood with duct tape on it then laid up 8 layers of fabric on it and finished off with a layer of peel ply. Then I wrapped the whole thing in plastic, stretched that tight and taped it down so the fabric would keep to the edge of the block of wood and not get any air bubbles in it.

Worked out pretty good.

I used the same method to make up some 'straps' for holding the rudder pedal tubes (and other static tubes) in place.

I used a piece of the tube taped onto a block of wood with duct tape.

This time I put the peel ply down first so that the bonding surface when done will be ready to use with no further work.

These are just stuck on with flock (with the tube taped in place till the flock hardens).

I made up all the blocks of plywood that hold the seat in position (I didn't take a photo for some reason). But then found that the seat itself doesn't fit very well at the front so it needed extending on the lower sides.

Pete says that final fitting is done with a load of micro on the floor of the cockpit (already covered with duct tape) and then the seat is just pushed into the micro and left to set. This should give a perfect fit when done.

Next up is the NACA inlet for the cockpit ventilation.

The duct supplied is for the old system of close-able vent. The manual calls for a air tight cavity to be made between the cell and the fuselage - made with expanding foam. Pete does not use this method and instead just has a scat hose connected to the NACA duct (of his own making) and then that connects to a cavity behind the vent control in the cockpit itself. Again this cavity is made by Pete.

I've decided to go the same route and modify the supplied NACA inlet by building a section behind it that transfers the air from the inlet to a hose.

I've sculpted this out of foam and it will be bonded onto the duct as a one piece unit when it is done.

I'm also trying a new method of making a mold plug out of foam. Rather than the sealing with micro and then sanding method. I read about it online and Pete says he uses it too so I thought I'd give it a shot.

Basically you just apply a thin layer of Micro slurry to the foam to fill any pin holes then straight away apply a thick coat of neat resin.

Allow that to set then just give the resin a light sand before painting and polishing and finally waxing.

Time will tell if this is the right way to go - it would certainly save a lot of time if it works.

|

| Panel with first coat of primer |

|

| Seat bottom needs extending - card with duct tape for shape |

|

| Panel mounts all layed up, taped up and setting |

|

| Wood block and tube for making up securing straps |

|

| Factory cut hole is a bit large for the cockpit vent - I'll have to fix that |

|

| Panel mounts and securing straps all done except for cutting out |

|

| NACA inlet and foam plug for connection to hose |

|

| NACA inlet fitting pretty good in hole. |

|

| Securing straps cut out |

|

| Panel mounts cut out - metal and rubber mounts will be bolted on eventually |

|

| Foam plug for inlet with micro and neat resin. |

Pete's 3rd Twister

As promised here are some photos of Pete's Twisters - from the day I spent up there recently.

|

| My proposed cowl inlet ring offered up to Pete's inlet - not too much difference here |

|

| Red lines indicate how my cowl will be shaped (open at the back on the sides) |

|

| Safety stays for the wing pins - a nice idea - I will be doing the same. |

|

| Cavity for cockpit ventilation - again I will be doing the same. |

|

| NACA duct with hose in the end - leading to air vent cavity. |

|

| Pete and his 'bomb' - ferry drop tank. 25 litres capacity |

|

| Pete says it took him 300 hours to build this... |

|

| Fuel pump and auto electric and fuel connections. Tank can take Smoke oil too. |

Subscribe to:

Posts (Atom)